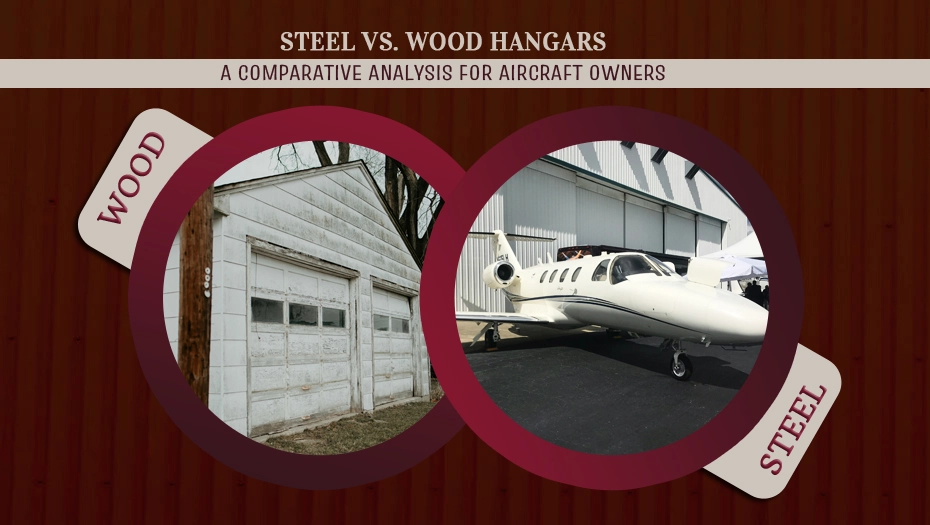

Steel vs. Wood Hangars: A Comparative Analysis For Aircraft Owners

Are you a proud aircraft owner looking for a storage aviation hangar for your beloved flying beast? If yes, you have come to the right place. Here, we will discuss metal airplane hangars, compare them to wooden ones, and see which one wins the bet.

As of now, the total number of active general aviation aircraft in the US is more than 300,000. Most of these are not part of scheduled airlines, but they include privately owned, club-owned, and single-airport company-owned airplanes. All of them need proper and secured shelter for a prolonged life.

Steel Vs. Timber Frame Airplane Hangars: Customizable

| The conventional size of aircraft accommodation is required to be 50 ft. x 40 ft. However, larger hangars are constructed and encouraged. With steel, you can build as wide as 300 ft. and as high as 40 ft. without any internal structural support beam. You can either insulate with fiberglass or use insulated metal panels (IMPs).

An aviation hangar for storage, repair, and servicing must be at least 2 ft. higher than the airplane itself. With steel, that’s easy to build. |

To get a large, unobstructed timber airplane hangars, you will need to add many wind braces and roof boarding for support. Even with this, you won’t be able to design a hangar 100 ft. x 80 ft. in size. |

| You can customize steel airplane hangars by design, shape, size, and external siding. | With wood and concrete, there is limited design versatility. |

| Steel structures can be easily insulated, making them suitable for various applications. | For storing airplanes, wooden structures need to be insulated. |

Steel Vs. Wood Hangars: Maintenance

| Steel airplane hangars require cleaning once or twice a year, depending upon their use. | Wooden airplane garage will need monthly pest inspection and control. |

| Steel is not affected by termites as it is dense and inorganic by nature. | Termites can easily chew, rest, and nest inside a wooden beam, frame, or panel. Once they are affected, it will take a large sum to eradicate them. |

| The overall upkeep cost of steel airplane hangars is lower than that of wooden counterparts. | Repair and replacement costs are generally higher with wood. |

Steel Vs. Wood Hangars: Strength & Security

| Metalaircraft hangars are made with rough, tough raw materials that can easily withstand daily wear and tear. | Wood is an organic material and is subjected to decay with time, even after maintenance. This won’t be good as hangars need to stay put from a structural integrity point of view. |

| Aircraft remain protected inside a steel structure, which is hard to break into due to its high density and strength-to-weight ratio. | Once it starts to decay, wood can be easily broken into. This will create a security issue. |

| In some places, it is mandatory to have a non-combustible material door for an airplane hangar. Steel is fireproof and offers many styles of doors, such as bi-fold, sliding, vertical lift, hydraulic, etc. | Wooden doors can’t offer any aircraft the same level of safety and protection as steel does. |

Steel Vs. Wood Hangars: Resilient

| A certified steel building designed by an engineer can withstand wind forces up to 170 miles per hour. | Wooden shingles will be airborne within no time as the high-speed wind hits them. |

| Certified metal with a 12-gauge frame and leg posts can tolerate up to 40 pounds per sq. ft. of snow load or even more. | Wooden building might collapse if it has too much snow cover over it. |

| Vertical steel roof panels offer less friction and a smooth surface with a high pitch that slides off dust, debris, and water from roof to ground. | Also, it is hard to clean snow from a wooden roof. |

Tip: Since metal airplane hangars are large structures, it is best to install a gutter with a downspout that sends water into a collection tank.

Steel Vs. Wood Hangars: Assembling Time

| Most parts of steel aircraft hangars are easy to assemble, as most of the designing, cutting, and drilling are done in the factory.

The simplest designs can be assembled within a few weeks. |

Installing complex structures like a wooden hangar would take 3 to 4 months. |

| e.g.: Nike air hangar (TVA architects, Portland), boat hangar (BETA office), Mosquito Coast Factory / Tolila+Gilliland, Boing Everett factory (Washington), etc. | e.g.: Hangar H16/Comte & Vollenweider, etc. |

Grab The Most Durable Metal Airplane Hangar From Viking Barns

We have 15 color schemes so that you get the perfect-looking aviation hangar for your property. Plus, with metal, you get the advantage of a lightweight, & long-lasting structure. Why wait? Give your aircraft the strong & secure storage it deserves. Call us at (704) 579-6966 Now!

You Should Also Read:

- Tips to Choose the Best Aircraft Hangar Manufacturer

- Why Metal Barns are a Smart Investment over Wood Structures?

- How Metal Barns Out-Perform Wooden Ones Every Time?

Alabama AL

Alabama AL

American Steel Carports Inc.

American Steel Carports Inc.