Frequently Asked Questions About Metal Hay Barn

Are you looking for more information on metal hay barns? If so, you are in the right place. We have covered all your frequently asked questions here! Whether it is about durability, certification, or maintenance, we have covered a wide range of Q&A for you. Let’s dive into the topic to learn more.

Metal Hay Barn Demystified: Your Top Questions Answered

Q01. What Is A Metal Hay Barn?

Ans. It is a hay barn made using modern structural steel primarily for storing hay, keeping livestock, and housing farm tools and equipment.

Q02. How Much Time Does It Take To Install A Hay Barn?

Ans. A prefab metal barn is mass-produced and designed in a factory away from the site. Additionally, metal is a dense yet lightweight material, making it easier to ship. At the construction site, assembling is done quickly, saving time. Installing a prefab steel hay barn requires less labor, so farmers save both money and time.

Q03. How Much Does A Steel Hay Barn Cost?

Ans. A metal barn costs between $15 and $40 per square foot, depending on the customization. In comparison, a wooden barn costs between $20 and $90+ per square foot. Moreover, metal barns require less maintenance than wood barns, which further reduces the operational cost.

Q04. What Are Common Sizes And Designs Available?

Ans. A standard size hay barn can be 40 ft. x 60 ft. and can hold about 5000 square size hay bales. Here are some of the sizes for your reference.

| Size of Hay Bales | No. of Hay Bale | Size of Hay Barn [Wide x Length x Height] |

| Typical Size Hay Bale | 1000 | 59’ x 105’ x 20’ |

| 2000 | 79’ x 158’ x 20’ | |

| 3500 | 89’ x 184’ x 25’ | |

| [Floor Space Per Ton] | ||

| Large Round Hay Bale | Stacked 2 High | 30 sq. ft. |

| Stacked 3 High | 20 sq. ft. |

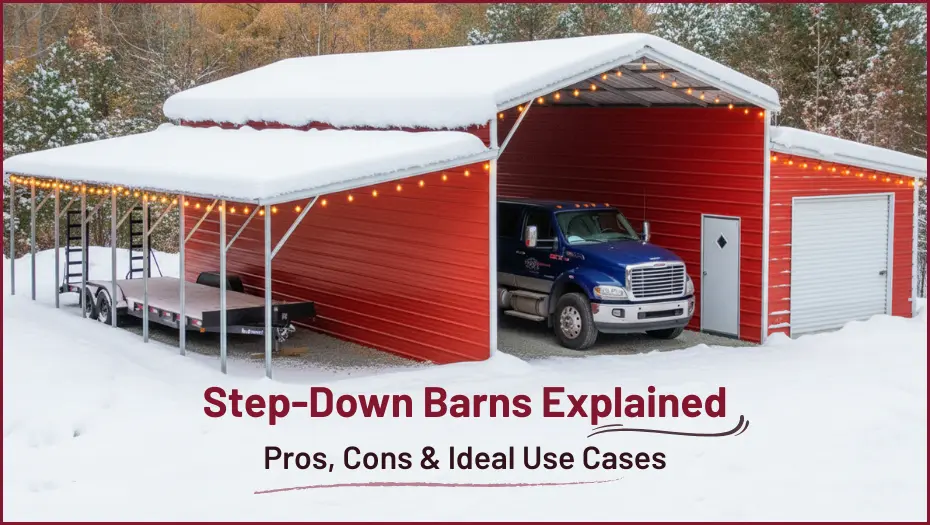

There are various designs, such as the Seneca barn, Carolina barn/ step-down barn/ raised center aisle barn, and Quonset hut. Let’s look at their dimensions.

| Type Of Metal Barn | Size [wide x length x height] in feet | Cost* [approx.] in USD |

| Vertical Roof Barn | 42 x 36 x 15 | 27620* |

| Seneca Barn | 40 x 50 x 12 | 37796* |

| Carolina Barn | 50 x 62 x 12 | 39283* |

| Metal Lean-To Barn | 54 x 60 x 16 | 39790* |

| Livestock Barn | 64 x 40 x 16 | 48405* |

Q05. Are There Permits And Regulations For Hay Barn?

Ans. Yes, you will need to secure a permit before installing a barn or any other construction work on your farm. For instance, a building meant to store hay bales must comply with the local building code and zoning laws.

The permit fee varies with location and type of construction and is generally between $50 and $150.

Q06. How Can You Customize A Metal Hay Barn?

Ans. You can customize a hay bale steel barn by adding any of the following:

- Insulation

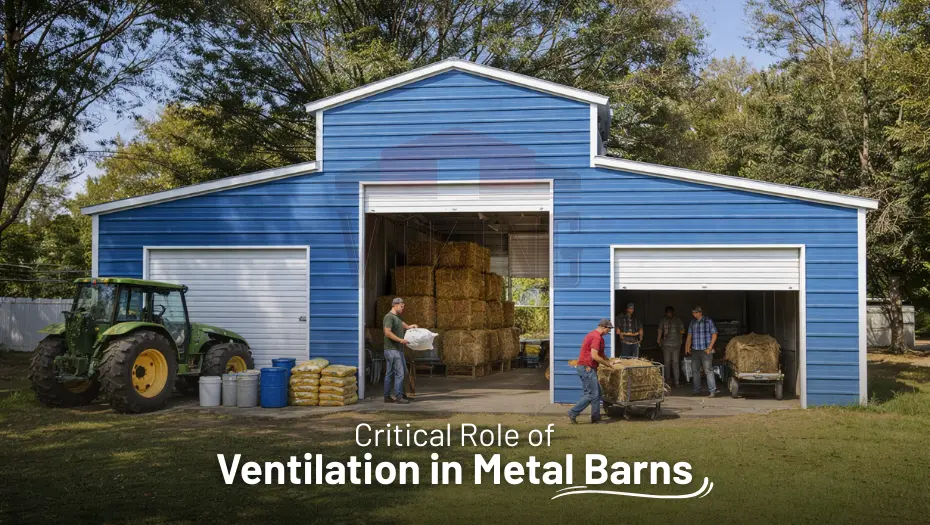

- Ventilation [exhaust fan, wind turbine]

- Color

- Lean-to [permanent metal awning on any side of the barn]

- Electric outlet [for lighting]

Q07. How To Choose The Right Location For Hay Barn?

Ans. You need to take care of the following when choosing a location for the hay barn:

- Good drainage

- Dry and high area

- Easy to access

- Enough space to maneuver [for loading and unloading]

- Centralized storage [sorting hay for sales]

- Proximity to feeding area [for feeding your own animals]

Q08. What Are Maintenance Requirements For Hay Metal Barn?

Ans. Metal barns are low maintenance barns compared to traditional structures.

Perform a regular check to find any cracks, dents, scratches, or rust on the metal roof, foundation, and side walls. If you find any issues, fix them promptly. For instance, if you notice any minor rust or faded paint, sand it, coat it with a metal primer, and then apply one or two coats of paint to prevent any major repair.

Use warm water with mild soap to clean your metal hay bale barn. Use a soft bristle brush to remove bird droppings or stains. After that, let it air dry before moving items back inside.

Q09. Does Metal Hay Barn Need Insulation?

Ans. Hay storage does not necessarily need insulation. It depends on your local climate and specific needs. For instance, insulation becomes necessary for the following:

- For extremely hot or cold regions [about 25% of the heat is lost via the roof in any building]

- To prevent metal from condensation due to changing interior temperature

- To make your barn energy-efficient

- If you want to use your metal hay barn as a multi-functional unit.

Insulation might increase the upfront cost but has long-term benefits.

Q10. Does Steel Hay Barn Come With Certification?

Ans. Yes, you can buy certified steel barns that can withstand high-speed winds of up to 180 miles an hour or a snow load of up to 80 pounds per square foot.

Q11. What Are The Benefits Of Using A Metal Barn To Store Hay?

Ans. Here are the following advantages of using a metal barn for keeping hay & feed and for other farm purposes.

- Durability

- Fire Resistant

- Quick To Install

- Overall Cost effective

- Customizable [As Per Need]

- Long Lasting Construction

- Pests Free

- Need Low Upkeep

- Weather Resistant

Metal Hay Barn Experts At Your Service – Viking Barns

Our metal hay barns can be tailored to the specific needs of your farm. They are quick to assemble and will last a long time with our top-quality raw material, which is 100% American manufactured. So, if you are looking for a durable barn that retains its structural strength for decades with minimal upkeep, call (704) 579-6966 to book one for your farm, livestock, & storage.

Whatever your farm needs, a metal hay barn is the way to go!

Alabama AL

Alabama AL

American Steel Carports Inc.

American Steel Carports Inc.