Building A Lean To Barn: A Step-By-Step Guide For Homeowners

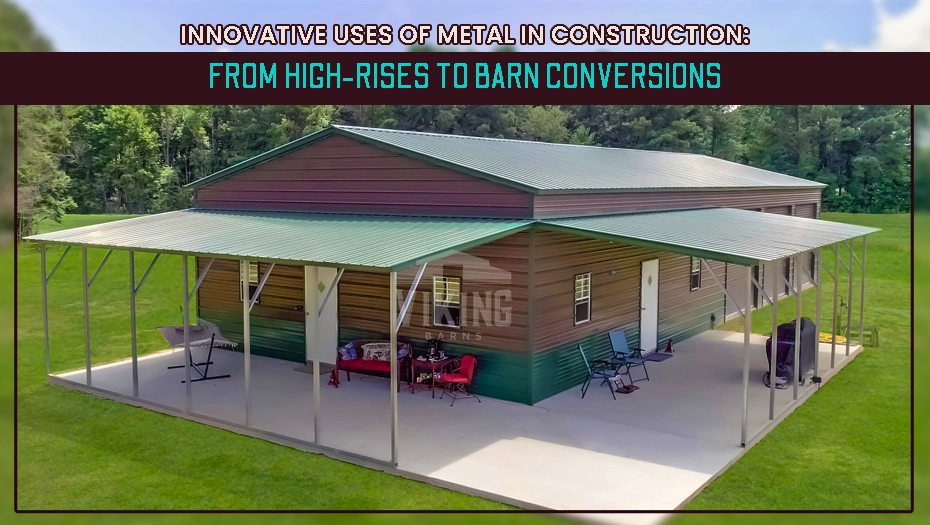

A lean-to metal barn is a great option for agriculture and businesses looking to invest in a new sturdy building that comes with low maintenance and lasts long without breaking the bank. Here, we will guide you through the entire process from start to finish, covering everything from choosing the right location to how to put it all together.

Installing Lean To Barns Made Easy: A Complete Handbook

Step 1 Planning For How To Build Barn Lean To

Choosing The Right Location & Size for Your Barn

Installing a barn correctly is as important as choosing the right barn location. It helps with:

- Easy access to the building

- Good drainage to keep the building moisture-free

- Future expansion [consider extra open space nearby]

Next, determine the purpose of your barn. Lean to barns are versatile metal buildings that can serve as storage, livestock shelters, workshops, event venues, or even restaurants. Having a clear primary purpose will help you decide on necessary accessories.

And finally, choose a design including height, width, roof slope, and the right materials. For example, you can choose between a 12-gauge and 14-gauge steel frame depending on local weather and zoning rules.

You can look at some of the metal building terminologies to understand the various components and installation processes involved in the construction of metal buildings. This will help you make informed decisions and communicate effectively with professionals during the barn project.

Step 2 Materials

List Of Materials & Tools Needed For Construction

Before beginning any construction work, you must have the proper tools and equipment ready with you. Once your order has been delivered, check if all metal barn and lean-tos components are there, such as a complete set of wall & roof panels, rafters, beams, purlins, screws, nails, and flashing.

Gather all the essential tools you will need for construction. Some of them are:

| Safety Equipment | : Hard hat, safety goggles, gloves, ear protection, safety harness, work boots, first aid kit, and fire extinguisher. |

| Hand Tools | : Claw hammer, adjustable wrench, multi-bit screwdriver, pliers, tape measure, ball peen hammer, spud wrench. |

| Power Tools | : Screw gun, drill, angle grinder, welding machine. |

| Heavy Equipment | : Forklift/ cane, telescopic boom lifts, man lifts, scissor lifts. |

Tip: It is important to level the ground, secure a permit, and follow all local building codes and guidelines to avoid legal issues and save money on metal buildings. You can get your lean to barns blueprint, submit it to receive a permit, and start preparing for the foundation.

Step 3 Foundation Tips: How To Build A Large Lean To Barn

Preparing The Ground & Laying A Solid Foundation

Clear the construction site and remove any debris, boulders, vegetation, and trees. Before removing large trees, check in with the local municipal office to see if it is protected [if so, you will need permission to remove them]. Now, you can level the ground to lay the foundation.

A metal barn with a lean-to can have three different types of bases: dirt & gravel, asphalt, and concrete slab/ pier. We suggest opting for concrete slab as it makes lean to barns versatile space.

Once you have decided on the base, start by:

- Marking the site by outlining the footprint on the ground.

- Dig post holes [ensure they are below the frost line].

- Set the post in the holes, level them, and fill it with concrete.

Now, let it dry so the concrete can harden and set. Once set properly, you can go to the next step.

Step 4 Framing

Instructions For Framing The Structure

- Start by installing the base rail and then install legs/ metal posts.

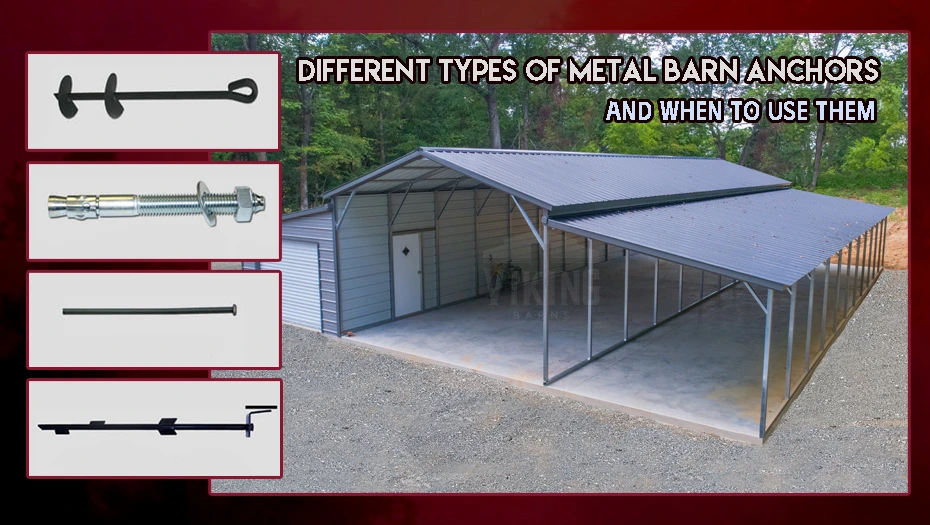

- Once the legs are in place, secure them with anchors so they stay firm during wild winds.

- Now, lay roof bows, purlins, hat channels. Secure it with braces.

- Attach the lean-to posts and beams along with the barn’s frame.

Tip: The frame will vary with the design of the barn. Choose a custom barn design to add value to your property. You can select width, height, clear span/ multi-span, length, and lean-tos on either side to increase its functionality.

Step 5 Roofing Styles

Installing A Durable And Weatherproof Roof On Your Barn

- Install roof panels and cover the tip of the roof with a ridge cap.

- The ridge cap seals the peak of the vertical roof to prevent rainwater leakage and entrances to insects.

- Be sure to place purlins evenly over the rafters so they can support weight equally.

- Choose corrugated vertical roof panels for less frequent cleaning, endurance, and longevity. They are best for lean-to barns.

- Add structural trim to support roof panels and provide extra durability.

- Secure roof panels with screws and fasteners. We offer matching screws that give a seamless look.

- Finally, install lean-to’s roof panels.

Tip: Choose a roof panel color according to your area. You can pick a light color for the moderate summery climate of Texas or a dark color for the harsh winter conditions of Pennsylvania.

Step 6 Siding: Enhancing Exterior Aesthetics

Options For Siding Materials And Installation Techniques

- Install side panels and walls to your metal barn.

- Start from one side and move towards the other.

- Make sure the panel’s ends are overlapped with each other.

- Finally, secure them with fasteners/ screws to keep them in place.

- Install corner trim to seal the metal barn walls.

Tip: You can choose metal siding and facades to improve the look of your barn and give it a personal touch.

Step 7 Doors And Windows For Easy Access

Adding Functional Elements To Your Lean-To Barn

- Add door frames out and window frames to the barn’s side walls.

- Now, you can install door & window panels.

- Add a walk-in door frame and panel if you have chosen a closed lean-to.

- Oil the hinges and secure them properly, as they are the most used parts of a barn.

- You can select wide & large roll-up doors, double doors, or sliding doors for your barn.

Step 8 How To Build A Leaning Storage Barn: Essential Accessories

Adding Insulation And Ventilation

Insulation is essential to keeping metal barns protected from moisture and condensation. It also reduces heat transfer, making the interior comfortable for humans and livestock. Currently, we offer insulation such as single bubble, double bubble, and woven R17.

Strategically placed ventilation to maintain a fresh airflow inside the barn. For example, there are roughly two types of ventilation systems for horse barns. Choose natural/ passive vents like ridge vents, turbine vents, and gravity vents if your barn is located in an open area without any nearby buildings or large trees.

Else, mechanical/active vents are best as they operate using power and give you more control over air circulation.

Step 9 Finishing Touches

Painting, Sealing, And Adding Final Details

Now that the entire skeleton of your barn has been installed with the walls, let’s move on to give it some finishing touches. We will start with paint. Usually, a metal barn comes with panels that already have the color you choose. However, during installation, if you notice any scratches or faded paint sections, we suggest giving them a touch-up to ensure the metal is protected.

Now, inspect the entire structure to see if there are any gaps. You can fill them with a silicone-based waterproof metal sealant that lasts. Finally, add signage, a mural, and low-maintenance, drought-resistant outdoor plants for a warm, welcoming look to your barn.

Step 10 Maintenance

Tips For Keeping Your Lean-To Barn In Good Condition

First, after the lean-to barn installation is complete, clean the entire structure. Be sure to remove any metal shaving, pieces, or extra screws lying around. These may rub against the metal surface and cause rusting. You can collect them and sell them to the nearest scrapyard. Avoid common mistakes while installing a metal building, such as failing to secure permits, improper site preparation, or installing fasteners the wrong way.

Keep a timely maintenance schedule for inspections, checks, and cleaning of the barn inside and out. Metal buildings don’t need very high upkeep, so you can clean them once or twice a year, depending on their use case.

Viking Barns: Your Go-To Guide For Building A Lean To Barn!

When installing a metal barn with lean-to for your business, home, or agricultural needs, you can follow these instructions, and don’t be afraid to ask for help if you need it. With a little patience and some elbow grease, you will have your very own lean-to barn up and running in no time! To get the latest price quote on your new custom barn, call (704) 579-6966 today!

Alabama AL

Alabama AL

American Steel Carports Inc.

American Steel Carports Inc.